Have you ever wished for a finish that not only looks stunning but also stands the test of time? Welcome to the world of UVLack! This revolutionary coating technology is turning heads and redefining surfaces across industries. Imagine vibrant colors, unmatched durability, and a sleek sheen all rolled into one incredible solution. Whether you’re a DIY enthusiast looking to elevate your home projects or a professional seeking quality finishes for clients, understanding UV-Lack could be your ticket to achieving breathtaking results. In this blog post, we’ll dive deep into what UV-Lack is, how it works its magic, and why it’s becoming an essential choice for anyone serious about surface transformation. Get ready to discover how this innovative finish can bring new life to wood, metal, glass—virtually any material you can think of!

UVLack utilizes cutting-edge science to transform ordinary surfaces into extraordinary ones. Whether you’re a homeowner wanting to upgrade your living space or a business owner aiming for longevity in your products, UVLack offers benefits that cater to all needs. Get ready to dive into the world of UVLack and discover how it can elevate your surfaces like never before!

How UVLack Works: The Science Behind it

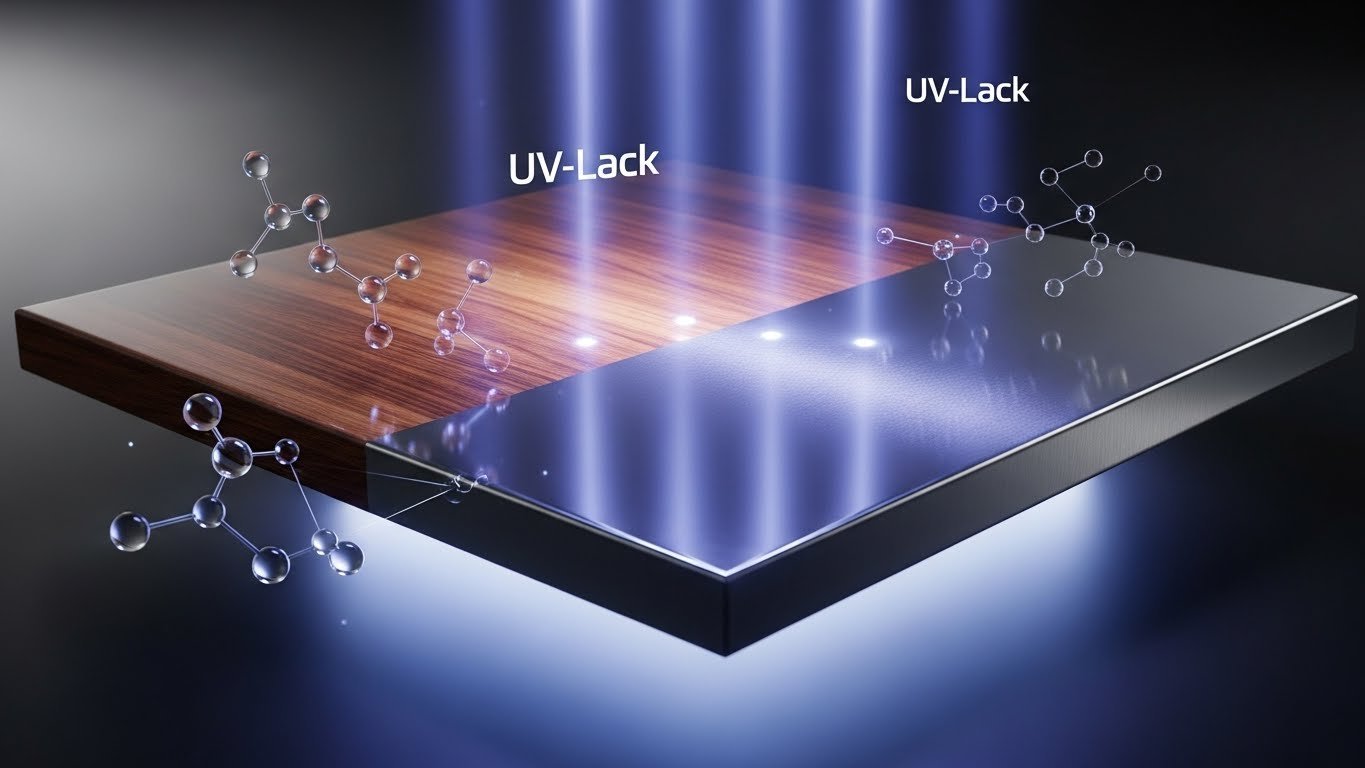

UVLack operates on the principles of ultraviolet light curing technology. This innovative process uses UV radiation to initiate a chemical reaction that solidifies the coating almost instantly. When applied, the liquid UVLack is exposed to UV light, transforming it from a viscous state into a robust finish.

The composition of UVLack includes specially formulated resins and photoinitiators. These components work together during exposure to UV rays. The photoinitiators absorb the energy from the UV light and trigger polymerization—a process where molecules bond together to form solid structures.

One significant advantage of this method is its speed. Unlike traditional coatings that can take hours or even days to cure, surfaces treated with UVLack dry within seconds under proper lighting conditions. This rapid curing minimizes downtime in various applications.

Moreover, once cured, the surface becomes highly resistant to scratches, chemicals, and environmental factors. The result is a durable layer that enhances both appearance and longevity.

As an eco-friendly option, many formulations of UVLack have low volatile organic compounds (VOCs). This makes them safer for users and less harmful to the environment compared to conventional coatings.

You Might Also Like: İns

Types of Surfaces that can be Transformed with UVLack

UVLack is incredibly versatile and can be applied to a wide variety of surfaces. Its unique formulation allows it to bond effectively, creating a robust layer that enhances both appearance and durability.

Wood surfaces benefit immensely from UVLack. Whether it’s furniture or cabinetry, the coating not only protects but also brings out the natural grain, giving it an elegant finish that stands the test of time.

Metal surfaces are another ideal candidate for this transformative treatment. From railings to appliances, UVLack provides a protective barrier against rust and wear while offering an attractive sheen.

Glass is often overlooked, yet UVLack works wonders here as well. It can provide a scratch-resistant finish on glass tabletops or decorative panels, adding both beauty and protection in one go.

Plastics are no exception. With its ability to adhere seamlessly to various plastic types, UVLack grants them enhanced durability while transforming their look with vibrant colors or sleek finishes. This broad range makes UVLack an excellent choice for multiple projects around homes and businesses alike.

Application Process: Step-by-Step Guide

Preparing the surface is crucial for a successful UVLack application. Start by cleaning the area thoroughly to remove dust, grease, and any contaminants. A smooth, clean surface ensures better adhesion of the coating.

Next, ensure that the environment is suitable for application. This means working in a well-ventilated space with controlled temperature and humidity levels. Such conditions will enhance curing times and improve overall results.

Once everything is prepped, mix your UVLack according to the manufacturer’s instructions. Proper mixing guarantees an even distribution of components. Take care not to incorporate air bubbles during this process; they can affect the finish.

Application can be done using various methods like spraying or rolling. Choose what works best for your project size and type of surface being coated. Apply evenly in thin layers rather than thick coats to achieve a flawless finish.

Cure the applied UVLack with ultraviolet light as specified by product guidelines. The curing process solidifies the coating quickly without compromising quality, resulting in a durable protective layer that enhances aesthetics effectively.

Advantages of Using UVLack over Traditional Coatings

UVLack offers a range of advantages that set it apart from traditional coatings. One significant benefit is its rapid curing time. Unlike conventional finishes that may take hours or even days to dry, UVLack hardens instantly when exposed to ultraviolet light. This efficiency allows for faster project completion and reduces downtime.

Another key advantage is the durability of UVLack coatings. They are resistant to scratches, chemicals, and UV degradation, ensuring long-lasting protection for various surfaces. Traditional coatings often fade or wear down more quickly under similar conditions.

The aesthetic appeal of UVLack also cannot be overlooked. Its high-gloss finish enhances colors and textures, providing a vibrant look that many standard paints lack. This added visual quality can elevate the overall design of any project.

Moreover, UVLack is environmentally friendly compared to solvent-based alternatives. It emits fewer volatile organic compounds (VOCs), making it a safer option for both installers and end-users alike.

Cost-effectiveness rounds out the benefits portfolio; while initial investment might seem higher than traditional options, reduced maintenance costs and longevity lead to savings over time.

Case Studies: Real-Life Applications of UVLack

One compelling case study involves a local furniture manufacturer who switched to UVLack for finishing their wooden products. This change not only reduced production time significantly but also resulted in a more durable finish that stood up against wear and tear. Customers noticed the difference, with many praising the quality.

In another instance, a commercial flooring company adopted UVLack for its epoxy floor coatings. The rapid curing process allowed them to complete projects faster without compromising on quality. Clients reported increased satisfaction due to the glossy, stain-resistant surfaces that were easy to maintain.

A high-end automotive shop found success using UVLack for custom paint jobs and protective coatings on vehicles. The scratch resistance offered by this innovative product kept cars looking pristine longer than traditional finishes could provide. Car enthusiasts loved the enhanced appearance.

Additionally, a kitchen renovation firm turned to UVLack for cabinetry finishes. They experienced fewer callbacks related to peeling or chipping paint since switching materials, which boosted their reputation among homeowners.

An outdoor signage company utilized UVLack to create vibrant signs resistant to fading from sunlight and harsh weather conditions. Their clients appreciated how well these signs held up over time while retaining eye-catching colors.

Tips for Maintaining and Caring for Surfaces Coated with UVLack

To keep surfaces coated with UVLack looking their best, regular maintenance is essential. Start by dusting and wiping the surface with a soft, lint-free cloth to remove dirt and debris. This simple step helps maintain the glossy finish that UVLack provides.

Avoid using harsh chemicals or abrasive cleaners on your coated surfaces. Instead, opt for mild soaps mixed with water for gentle cleaning. These alternatives will protect the integrity of the coating while ensuring cleanliness.

It’s also wise to steer clear of excessive moisture exposure. While UVLack offers excellent water resistance, prolonged contact can still affect its durability over time. Make sure to dry any spills promptly.

For high-traffic areas or surfaces prone to scratches, consider applying a protective layer or mat over them when possible. This proactive measure can shield your investment from wear and tear.

Perform periodic inspections of your UVLack-coated items. Look for signs of damage or wear that may require touch-ups or repairs before they escalate into more significant issues down the line.

Potential Drawbacks or Risks to Consider

While UVLack offers many advantages, it’s essential to consider potential drawbacks. One primary concern is the initial cost. The investment in UVLack can be higher compared to traditional coatings, which may deter some users.

Another factor is the application process itself. Achieving optimal results requires specific equipment and expertise. If not applied correctly, it can lead to uneven surfaces or premature wear.

Environmental conditions also play a role in effectiveness. High humidity or extreme temperatures during application may impact curing times and overall performance of the finish. This unpredictability can be frustrating for those looking for consistent results.

Health considerations are worth noting as well. Although modern formulations are safer than older products, proper ventilation and protective gear remain crucial during application to minimize exposure to fumes.

While UVLack provides impressive durability, it’s not entirely impervious to damage from harsh chemicals or physical impacts. Users should still exercise caution with cleaning agents and heavy objects that may scratch or chip the surface over time.

Alternatives to UVLack and Why it Still Stands Out

When exploring alternatives to UVLack, several options emerge. Traditional varnishes and lacquers are common choices but often lack the durability that UVLack provides. These coatings can wear down quickly, leading to frequent reapplication and more downtime.

Water-based finishes offer a greener solution with low VOCs. While they’re easier on the environment, their resistance to scratches and chemicals doesn’t match up with what UVLack delivers. This makes them less suitable for high-traffic areas or surfaces requiring robust protection.

Epoxy coatings shine in specific applications like flooring, where strength is crucial. However, they can be challenging to apply and may take longer to cure compared to the rapid process of using UVLack. The ease of application sets UVLack apart.

Powder coating is another alternative known for its toughness but lacks versatility when it comes to different surface types. It’s mainly used in industrial settings rather than for intricate designs or fine finishes you might want at home.

What truly distinguishes UVLack is its quick curing time under ultraviolet light combined with an impressive finish quality that rivals traditional methods while providing unparalleled protection against wear and tear.

You Might Also Like: Afruimwagens

Q&A: Addressing Commonly Asked Questions

Many people have questions about UVLack, and it’s understandable. This innovative coating has gained popularity for its durability and versatility. Let’s address some common queries.

One frequent question is whether UVLack is safe for indoor use. Yes, it emits minimal volatile organic compounds (VOCs), making it a suitable option for various environments, including homes and offices.

Another concern revolves around the curing process. How long does it take? Typically, UVLack cures almost instantly upon exposure to UV light. This quick drying time allows for faster project completion without compromising quality.

People often wonder about maintenance requirements too. Surfaces treated with UVLack are relatively low-maintenance but should still be cleaned regularly with mild detergents to preserve their finish and luster.

Many ask if UVLack can be reapplied over existing coatings. The answer is yes! However, proper surface preparation is essential to ensure optimal adhesion and performance of the new layer of coating when reapplying or refreshing surfaces coated with this technology.

Final Thoughts on the Transformative Power of UVLack

The transformative power of UVLack is nothing short of revolutionary. As industries continually seek innovative solutions for surface protection and enhancement, UVLack stands out as a leading choice. Its unique curing process not only offers durability but also delivers an aesthetic appeal that traditional coatings often struggle to achieve.

Imagine surfaces that are not only more resistant to wear and tear but are also visually stunning. Whether it’s in commercial spaces or residential applications, the versatility of UVLack can cater to diverse needs while offering unmatched flexibility in design and finish.

While there may be considerations to keep in mind, such as application techniques and potential drawbacks, the benefits typically outweigh these concerns. With proper care and maintenance, surfaces treated with UVLack maintain their brilliance over time.

As you explore options for enhancing your surfaces—be it furniture, flooring, or fixtures—consider how UVLack could change your approach entirely. The fusion of science and art found in this innovative product unlocks possibilities previously thought unattainable. Embrace the future with UVLack; it might just redefine what you expect from surface treatments.